From a small section of a steel square bar, you can make a real blacksmith anvil with your own hands. Only miniature sizes. It’s definitely impossible to “beat off” hot billets or straighten nails on such an anvil.

However, this craftwork looks very worthy as an original souvenir - you can, for example, present this trinket to a friend blacksmith. To make such a miniature anvil, you need to do a little work with your hands. But the end result is worth it.

The main stages of work

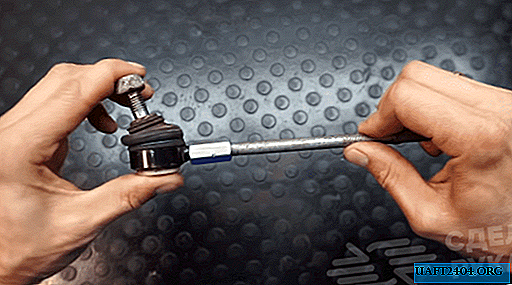

For the manufacture of a blacksmith anvil, a small segment of a steel square with a side size of 20x20 mm is required. We tightly clamp the workpiece in a vise, after which we arm ourselves with a hacksaw and a file for metal and proceed to the machining.

First, the main contours of the blacksmith anvil are made, then a horn is formed - at this stage you will have to work hard to give it a rounded shape. Then cut the workpiece in length and make a "tail" in which, as expected, we drill a hole.

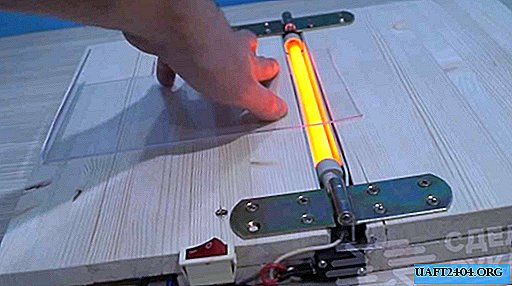

At the last stage of work, we give the correct shape to the paws, and then we process the front working surface of the anvil on a diamond bar. After that, we heat the product with a gas burner and quickly cool it in a container with water.

Additionally, you can cover the surface of the blacksmith anvil with a special spray, which provides additional protection against corrosion. For a detailed process of making this homemade product, see the video on the site.