Share

Pin

Tweet

Send

Share

Send

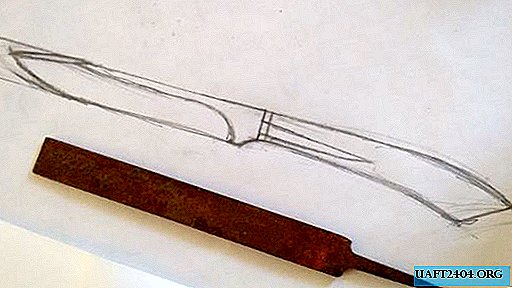

I found an old file at the flea market and decided to make a knife out of it. I had no desire to heat it up or to polish the blade for hours. Therefore, with minimal processing, I constantly kept the temperature of the blade cold. Work took about 2 days (including glue drying time).

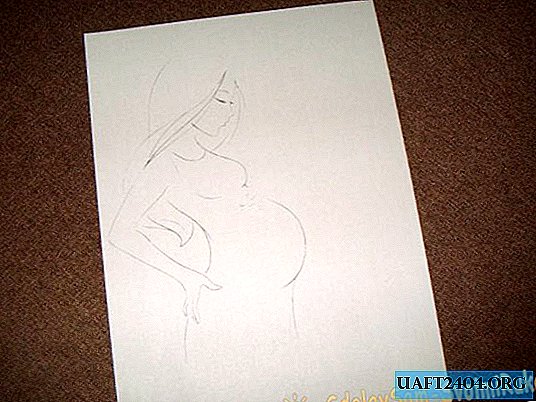

Knife design

I manually sketched the design of the future knife (taking into account the width and thickness of the file). But I didn’t put an end to it, and in the process I was ready to correct the form.

File Processing

First I worked the shank, then I went to the tip. All this was done on a grinder. Then I began to grind the descent in my eye, which came out well - not perfect, but I liked it. During processing, I did not allow the file to heat up, from time to time dipping it into a glass of water so that the steel does not become soft. This was easy to admit, as the thinner the file became, the faster it warmed up. Something attracted the butterfly, and it remained on my arm throughout the process.

Knife blade processing

Then, using P60 sandpaper, I made the surface smoother. The notches were left because grinding them would take a long time. The blade turned out with concave descents, because the sharpening was carried out on the circle of the grinder. I did not expect the surface to be more even.

Handle

The handle is made of a 6 mm thick brass plate and a bar of purple amaranth. I chose them because brass and magenta blend well. In brass, I drilled two 5 mm holes and connected them with a drill and a hacksaw blade. Usually in such cases, people use different files, but I don’t have them, and I didn’t strive for perfection. The shank through the bolster was inserted into a 5 mm hole in the tree, pre-filled with epoxy.

Shaping

I let the glue dry overnight, after which I started processing the handle. At first I cut the bar in half, bringing its length almost to the desired one. After that, I clamped the knife with a clamp and started processing using the disk of a grinding machine with grain P120. When working with bolster, care must be taken, since the tree, in comparison with brass, grinds much faster. After the profile took the desired shape, I proceeded to grinding the sides, giving them a rounded appearance. The whole process took about an hour.

Polishing

Having processed the handle with sandpaper with grain P240, using a polishing wheel, I made its surface smoother. There were still scratches on it, but I liked them. After that, the tree was impregnated with Danish oil (4 layers with easy grinding in between). Then I sharpened the end of the handle with a donkey.

The amaranth tree, oxidizing over time, becomes more purple, and in the photo it seems even more red.

Thanks for your attention!

Original article in English

Share

Pin

Tweet

Send

Share

Send