If you are servicing your car yourself, without resorting to the services of a car service, then this homemade product will definitely come in handy on the farm - using a universal vice, you can quickly disassemble the suspension struts, as well as perform other technological operations. Let's not waste time and immediately move on to the manufacturing process of this device.

How to get started?

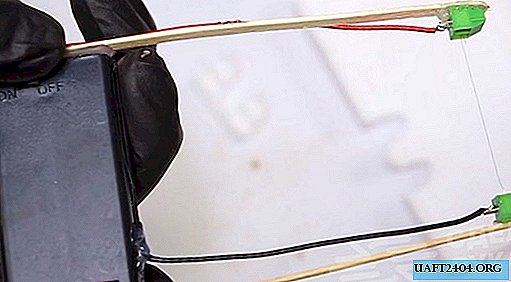

First you need to take a steel equal-angle corner 63 mm (or any other that is at hand in the garage) and with the help of a grinder cut out two plates with a width of 25 mm from it. Then from these plates it is necessary to cut four identical strips 200 mm long each. On the edges of the resulting workpieces, drill holes with a diameter of 10 mm.

Then, from the steel corner of 25 mm, two pieces of 50 mm wide must be cut off by the grinder. If desired, these details can be done more. In the steel plates in the center it is necessary to make a cut - to make a marking, it is enough to attach a piece of a corner of 25 mm to the base (a triangle should turn out). Such slots need to be cut in all four blanks.

From a piece of a 200 mm channel (9 mm thick), it is necessary to cut a strip 28 mm wide and 140 mm long and mark it with 5 holes at an equal distance from each other, and then drill.

Assembly assembly

As a basis, you need to prepare a steel profile pipe 20x20 mm (length at your discretion). To assemble all the workpieces into a single design, you will need to use a welding machine or ask a friend's welder. The detailed assembly process can be seen in the video on our website. Such a universal vice can be used not only for disassembling the suspension struts, but also for other works - for example, for processing steel pipes.