With the help of a home-made drill in the form of a “blade”, it is possible to drill horizontal or vertical holes of large diameter in wooden workpieces. In this case, the inner walls of the hole will be smooth. To make such a drill, you need a piece of a steel plate 70x50 mm.

If you need to drill a hole of a larger diameter, then the dimensions of the plate in this case will be different. We make marking with a marker, and cut out a small groove with the help of a grinder.

There is no need to excessively try to align the edges with a metal file, since all the “defects” will hide under the weld. We insert a piece of screw or hairpin into the cut-out groove, then we scald it.

The main stages of work

After the stud has been welded to the plate, it is necessary to clean the place of the weld using a grinder with a petal disk. The length of the tail of the stud should be at least 8-10 cm.

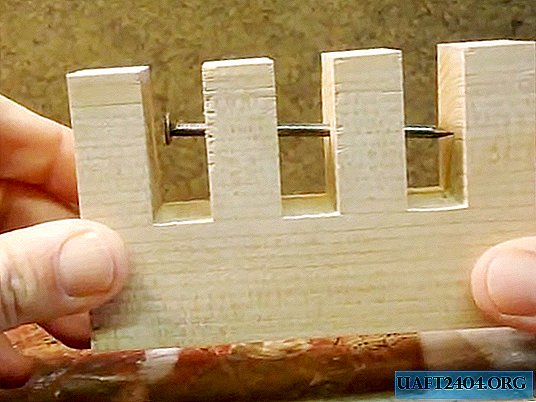

In the lower part of the plate we cut two pieces at an angle of about 45-55 degrees. The result should be the shape of the scapula. After that, we sharpen the edge on both sides. And in the upper part of the scapula it is necessary to cut two pieces at right angles.

At the last stage, it remains only to test the drill in work on a drilling machine. If there is a strong beating, then the length of the shank can be shortened a little by 3-4 cm. For more information on how to make a "spatula" drill on a tree, see the video on the site.