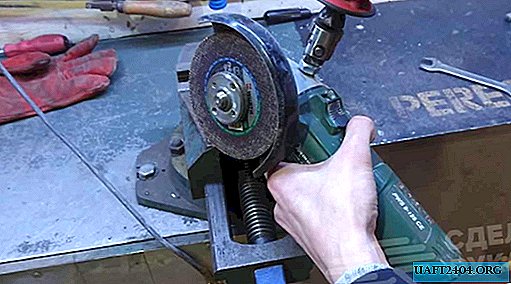

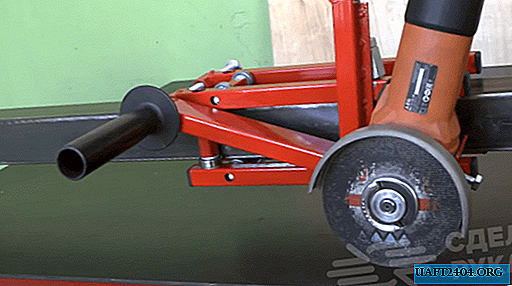

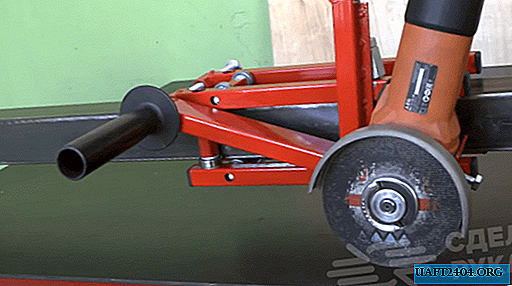

Using a simple home-made stand with a carriage for a small grinder, you can perform machining of a variety of materials. In particular, this design allows cutting sheet metal, as well as profile pipes.

Moreover, by installing a small grinder on such a makeshift rack, you can cut the workpiece from almost any angle. If you install alternative cutting discs, you can cut other materials: plastic, ceramics and wood.

Please note that the maximum length of a workpiece (sheet or profile), which is "tough" for a small grinder, can be different - in fact, it is limited only by the length of the guide from the profile pipe.

The main stages of work

First of all, we cut four pieces of equal length from a square profile pipe. Then we mark and drill holes of different diameters: first on one side of the profile, then on the other, which is perpendicular.

At the next stage of work, we wind three elongated nuts on a hairpin and weld profile pipes to them. A thin profile is best cooked semiautomatically. But in an extreme case, it is also possible by electric arc welding, choosing suitable electrodes.

Next, cut off two identical rectangular plates, drill holes in them. Then we fasten them to the grinder body. Then we weld the “ears” to a wide profile. It will still need to weld a small section of the profile pipe at an angle.

At the last stage of work, we clean the blanks with a petal disk and paint. Then proceed to the assembly. We recommend that you look at how to make a home-made rack with a carriage for a small grinder in the video on our website.