When performing large amounts of work on carpentry or metal processing, speed plays an important role. Therefore, a quick-clamping clamp on the farm will always come in handy. And you can do it yourself with metal strips.

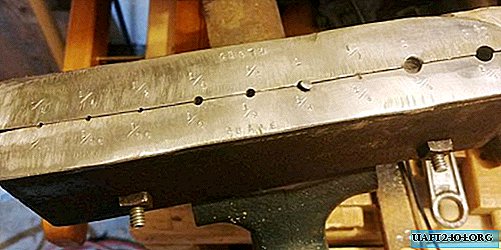

First you need to determine the size of the clamp, and then you need to cut from strips of metal workpieces of suitable length.

Next, you will need to weld together three pieces (one long and two shorter) perpendicular to each other. Before welding, it is important to align the plates exactly at right angles. To do this, you can use the magnetic corner.

The main stages of work

At the next stage, the master welds the clamping sponge to short strips (from an unnecessary section from the old file). Then parallel to the upper plates you need to weld another 2 strips of metal. They must be mobile. A nut is also welded to them in the middle.

Next, a second clamping sponge is cut out of a metal plate. A slot must be made at one end so that it can be inserted into the nut. After that, a "lock" is made by welding.

At the last stage, the master makes the missing parts and proceeds to assembly. The result was a useful tool for the home workshop and garage.

Details on how to make a quick-clamp clamp from metal strips with your own hands, you can see in the video on the site.