The circular saw blade used on stationary circulars is an excellent material for making knives. And in this case, the author decided to make a rather unusual cleaver knife out of a circular saw.

The first step is to draw a knife template on paper. You can draw your own template or download a ready-made one from the Internet.

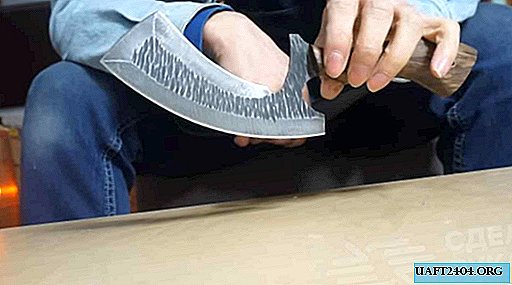

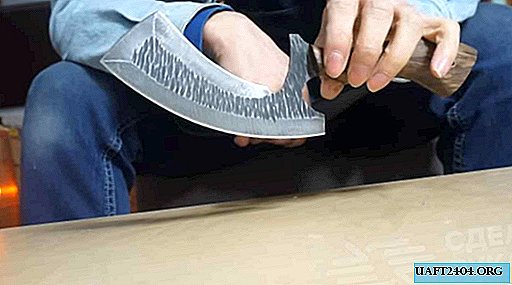

Next, you need to cut out the template, transfer it to the saw blade and circle the contours with a marker. And for convenience, you can fix the paper template with neodymium magnets, so as not to accidentally move it. Then the workpiece is cut using a grinder.

The main stages of work

After the workpiece is cut, its edges must be filed to remove burrs. Then the master forms the cutting edge of the knife on the grinder (grinder).

At the next stage, the blade is quenched (the metal is heated red-hot at a temperature of about 860 degrees, after which it is cooled in oil) and tempering. Then, using a grinder on the surface of the knife, the master makes “scales”.

This is followed by processing the knife in ferric chloride, after which you need to rinse it in a soda solution. As a result, the product acquires a beautiful matte shade. Then it remains only to make a wooden handle.

For details on how to make a knife of an unusual shape from a circular saw for circular saw, see the video on the website.