Share

Pin

Tweet

Send

Share

Send

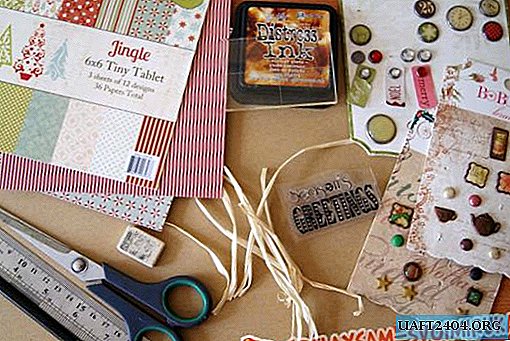

Would need:

- modern effective paint remover;

- medium brush;

- a piece of cloth from a hacksaw for metal;

- polishing paste, for example, for grinding in valves;

- source of running water;

- grinder and polishing foam grinding wheel;

- soft paper or fabric napkins;

- a toothbrush or a small brush;

- solvent (white spirit, 646, kerosene, etc.);

- black nitro paint and means for its application.

The process of polishing the engine cover

We use the usual sequence of actions in such cases:

- we remove all unnecessary (paint, protective coating, layers, etc.);

- we derive mechanical damage (scratches, risks, chips, etc.);

- We carry out the polishing process.

Removal of paint, layering and surface restoration

To do this, use a tool to remove old paint.

Carefully apply it with a brush on all surfaces, including recesses, corners, transitions and holes.

After some time, with a piece of a hacksaw blade, we scrape off the softened and exfoliated coatings, including those formed during operation.

Next, we continue the process of cleaning and removing damage from the surface of the engine cover using waterproof emery paper, first with a grit of P 220, and then with P 400, having slightly moistened the working side of the emery cloth and the cover with water slightly before starting.

When switching from sandpaper with a larger grain size to a smaller one and upon completion of this stage of recovery, the part is thoroughly washed with running water.

This will remove large particles of abrasive and metal, and create acceptable conditions for processing the engine cover with a material with fine grain.

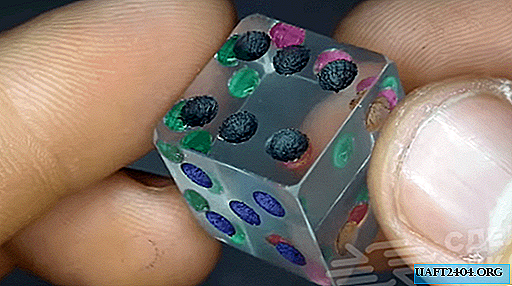

Polishing engine cover

After the previous step, the part should be clean and not have visible marks, scratches, chips and chippings. If so, then you can proceed to the first stage of polishing.

To do this, we use a polishing paste such as a means for grinding in the valves.

Squeeze a small amount of paste onto the surface of the part and distribute it to all places, including hard-to-reach ones, using a special tool or just with your fingers, after which you should wash your hands with soap and other hand detergent.

For polishing, we use a foam circle mounted on the grinder spindle. You should not particularly press the tool, but the speed should be high.

After the first polishing is completed, the part is thoroughly wiped with a soft paper or fabric napkin.

Again, apply a small amount of polishing paste to the engine cover and distribute it over the entire surface and repeat the polishing, as in the first case, completing the process by wiping the part with a soft cloth.

It remains to clean the symbols of the name of the engine brand squeezed out on the cover with a toothbrush and any tool such as white spirit, solvent 646 or just kerosene.

After the brand marks are completely cleaned of old paint, rubbish and other contaminants, using a suitable rod, we distribute black nitro enamel over all the signs. If necessary, carefully remove excess paint and let it dry.

After a comprehensive cleaning, restoration and polishing, the engine cover acquired its original appearance.

Share

Pin

Tweet

Send

Share

Send