Share

Pin

Tweet

Send

Share

Send

A year ago, I presented my niece with a projector of the starry sky. Under the black upper dome of this lamp there are three or four monochrome LEDs which, through the transparent areas of the black dome, project figures (I have moons and stars) onto the wall and ceiling.

In my case, there were four half-watt LEDs: Red (red), Green (green), Blue (blue) and separately White (white). The projector is equipped with LED switching modes, which allows them to form additional colors and shades by turning them on differently.

Also, the frame, in which a black hemisphere with transparent patterns is fixed, is motorized and can rotate around a vertical axis.

Although I believe that my purchase was quite successful, and as a finished device, the purchased lamp fully justifies its $ 8, I suggest that assembling the lamp with your own hands is not worse, and in some respects it is much better than what I bought a year ago.

Lamp manufacturing

Shade

It can be ready, for example, matte spheres from street lamps, or spheres from granular polystyrene - this option would be best, but I didn’t have either.

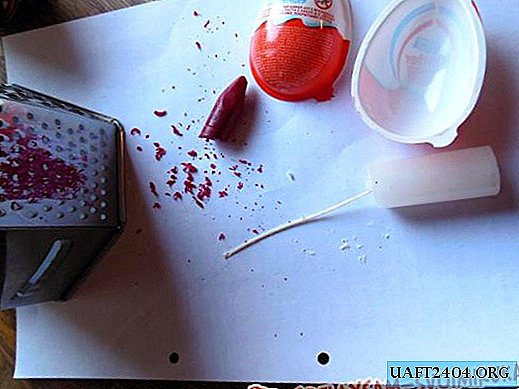

I have prepared:

- - PVA glue;

- - ball made of thin rubber;

- - narrow paint brush;

- - a small screwdriver;

- - a spray gun of very fine atomization of water;

- - one sixth roll of two-layer paper towels;

- - stand in the form of a torus, any.

Since the towel is two-layer, its sheets will have to be divided. This version of the lamp is not the first, and this time, I decided that a thinner shade would look more profitable, and in addition, it would absorb less light.

If possible, tear sheets of towels into chaotic shreds, do not be lazy. The type depends on this and whether the joints will be visible on the surface of the ceiling.

Set the ball on a stand, moisten its surface with a spray bottle and with an overlap, lay the first layer of paper scraps.

A hole should be formed in the future ceiling and leave free space for it.

Make sure that the paper is evenly moistened, let our first layer dry a little and start applying PVA glue

And then, impose a second layer of paper. Apply glue with wide tangential brush strokes. To avoid spreading dirt and not soiling your fingers, use a screwdriver (or a lancet, spatula, spatula) to hold scraps of paper in place.

Let the second layer seize for an hour or two, and in the same way, apply the third layer, which is on top, fix with another layer of PVA glue.

Lay a sheet of paper between the ball and the ring-shaped base, and leave the sphere alone for a day.

A day later, I cut a window in the ball:

And he carefully removed it from the paper sphere:

Strengthening the scope

This time, unlike the previous one, I decided to strengthen the sphere from the inside. To do this, I needed a transparent glue from a hardware store. I don’t know how it will be with you, in its composition, there is one single line “vinyl acetate copolymers”.

I poured into the sphere a fifth of a half-liter bottle of glue, and rotating the sphere, evenly distributed the glue on the inner walls. As soon as the glue reached the neck, I set the sphere on top of the empty yogurt packaging and left the case for another day.

Now, transparent glue should be applied, starting from the opening of the neck of the sphere in a spiral downwards - this will be the most uniform way, as soon as the adhesive reaches the equator of the sphere, put the sphere on the stand and the entire structure on the newspaper.

Excess glue will drip and harden. If there are holes in the adhesive coating somewhere, tighten the adjacent layer of glue with a spatula or the end of a knife.

After half a day, with a razor blade, cut off the frozen flows and drops. Flip the sphere 180 degrees, and apply glue to the previously clean upper north pole of the sphere.

Allow the glue to harden completely for at least 24 hours.

Everything, the ceiling is ready, go to the stand.

Stand

By chance, in my garage, they had four rings made of a material similar to a synthetic “clay” that solidifies after heat treatment. But, as such a stand, any object similar to a bagel will do. He came up and sawed a thick branch of a suitable diameter. In addition, such a stand can be cast from epoxy resin or from gypsum mixed with PVA glue. Of your choice.

For an electric cord, I drilled a through hole at the end of the stand, and sanded the stand itself.

As inserts, I cut out several circles from cardboard. To save them, I cut the same mugs from foam polyethylene. I did not want to mess with the foam, but the cork can be cut out of it.

I cut a separate circle from a piece of linoleum, and in three cardboard circles I cut vertical slots to fix the future circuit board.

In a glued sandwich, I cut out triangular sectors for free passage of the power cable.

As can be seen from the photo below, the circuit board will protrude above the surface of the stand, this is done intentionally, for more uniform illumination of the ceiling from the inside.

Electronic part of the lamp

In addition to the circuit board, I needed thirty pieces of the so-called slow flash LEDs and thirty current-limiting resistors of 470 ohms each.

The assembly process is a little monotonous. Fourteen diodes are located on one edge of the circuit board, fourteen on the other, and two on the end.

Since we are not engaged in industrial production, but piecewise - then try =)

Although all the LEDs start at the same time or in different ways, they reach already at the fifteenth second.

I inserted a regular switch into the power cord, and soldered the USB plug to the other end, the lamp can be powered from any device with a USB port.

On the back of the stand, I glued five anti-slip pads carved from a deflated ball.

Having put the ceiling in place, it's time to admire the result.

Most of all, the resulting ambient light (Ambient light) is similar to some satellites of Saturn.

And sometimes, to the moons of Jupiter.

Conclusion

The most important is the arrangement of the lighting of the ceiling. In a purchased lamp, (apart from just white), three sources of monochrome radiation of the optical range are used - in aggregate, this is one RGB triad, in my version, there are thirty such triads.

In the purchased lamp, there are several algorithms for controlling the LED triad and they are limited by options, in my version, each LED has its own random number generator, which guarantees the uniqueness of switching crystals for at least twenty minutes.

Although separate monochrome LEDs are used in the finished projector, there are LEDs that technologically combine three.

Each crystal can be controlled independently by corresponding electrodes. And it seems to me that I saw lamps assembled on such hybrid LEDs.

Those LEDs that I applied are self-managed, it is not possible to change the crystal switching algorithm, but it is not necessary either.

The color picture created by thirty independent random number generators is many times richer and more attractive than with any purchased lamp.

And of course, this is satisfaction from the work done.

I accelerated the video several times.

Share

Pin

Tweet

Send

Share

Send