Share

Pin

Tweet

Send

Share

Send

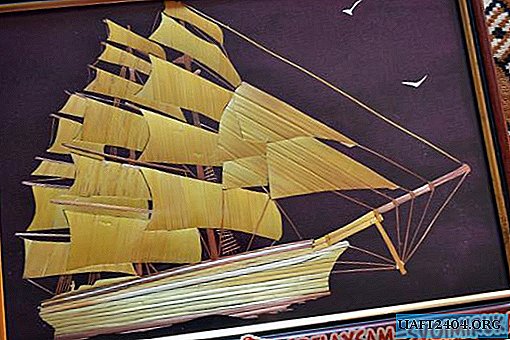

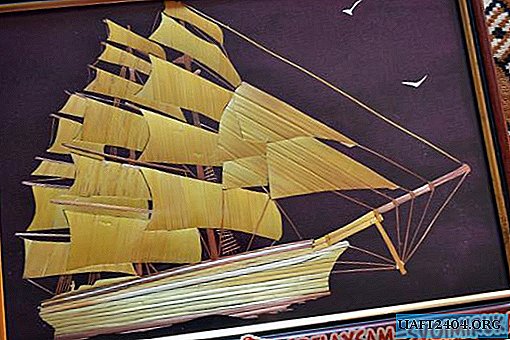

After all, our team today offers not just a trip, not just to learn the art of sailing from experienced sailors, but to create an indescribable beauty of a sailboat itself, which exudes the master’s love for his work with every detail. And as you dare to guess, without exaggeration, we will make a picture of a magnificent frigate! And our amazing material for this is simply, usually - straw stems. Want to plunge into real marine life, becoming a voluntary member of its crew? Would you like to be a helmsman on a watch at the helm? Do you want sea knots, climbing a mast and sailing emergency? So, the role of a wonderful shipbuilder is yours. And that means full speed ahead!

Stage 1 - harvesting.

For work, rye, barley or oat straws are best for us. First, you need to select a high-quality middle part of the collected straw stems. To do this, the cut ears are cleaned of integumentary leaves, cutting off the corresponding nodules. The result is ordinary straw tubes of various lengths. Further, the tubes selected by us are placed in a container of water and boiled for half an hour to acquire special strength, softness, flexibility and elasticity. Then, neatly, most conveniently with an ordinary knife, the tubules must be cut along the stem, along their entire length and flattened with an iron on both sides. The result of this work is the straw ribbons we need.

Stage 2 - manufacturing of parts.

We have a complete sailor kit: scissors, tweezers, a pen or pencil, PVA-K glue, and a base for gluing (background). The background in our work will be chosen dark purple velvet fabric, carefully glued around the perimeter of a dense base (cardboard).

The most interesting:

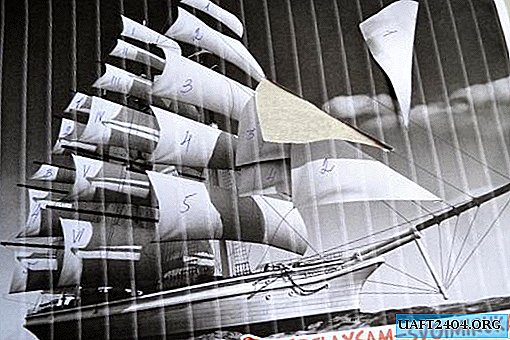

- Create a sketch of our frigate, enumerate all its individual components and carefully cut them out, clearly along the contour lines.

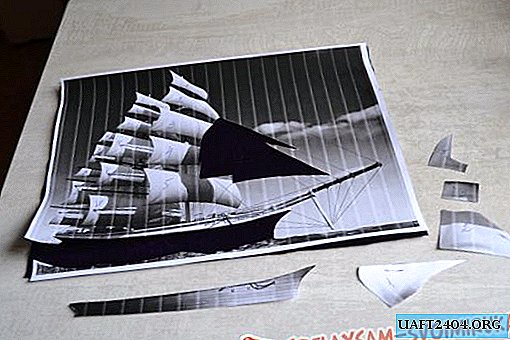

- We lubricate each cut-out paper detail of the sketch with glue (front side) and glue our straw ribbons tightly to each other, be sure to select the correct direction and color combination of the straw. The resulting elements of the part are laid aside until completely dry.

- We dry the dry parts again on both sides and cut off excess straw from them, clearly guided by the outline drawing of the wrong side of the details of our paper sketch.

Stage 3 - forward, for a dream ...

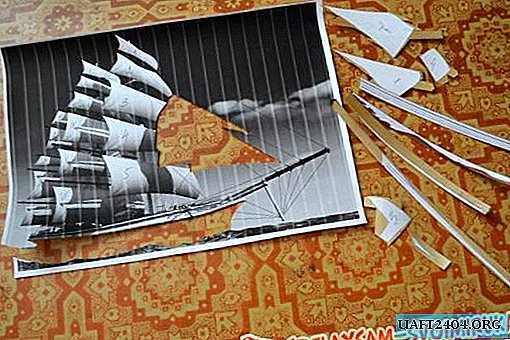

The resulting numbered details of the sailboat are laid out on the basis of the manufacture, thereby checking their presence, accuracy in the inclination and location. After making sure of the correctness of the test result, eliminating any inaccuracy, we proceed to the phased gluing of each individual element to the base. So the complete drawing will be folded easily, quickly, accurately and correctly. The final and mandatory stage of work - we leave the entire product under the press until it completely dries. And you want to decorate your sailboat, protect it from the effects of dust and time - place it under the glass ...

That's all! A sea cruise aboard our sailing frigate is not only an immense distance, a fresh breeze, snow-white sails, spacious decks and comfortable cabins, it is a rich legacy of the work of this team!

Share

Pin

Tweet

Send

Share

Send