Share

Pin

Tweet

Send

Share

Send

For economic reasons, the cross section of the pipes should be chosen as minimally possible, but on the verge of functioning. The cross section of the collectors themselves should also be small, since all these obstacles can impede circulation, which can increase the hydraulic resistance of the entire system. One cannot do without a circulation pump in such a system, since the coolant must be forced to move. This makes the collector system dependent on electricity, and also reduces its viability.

Installation of a heating system.

1. In this private house, a floor gas boiler is installed in the basement. The boiler is mounted on a concrete screed five centimeters thick.

2. To the "feed" and "return" of the boiler we mount metal pipes having a diameter of 32 mm.

3. On the "feed" pipe we install a closed expansion tank.

4. Next, we install a collector on the "feed" pipe.

5. On the pipe "return" install a circulation pump.

6. Cranes must be installed on both sides of the pump. This is necessary for convenient replacement of the pump in case of failure. In this case, you do not have to drain the coolant.

7. On the pipe "return" we mount a tap through which the system will be fed.

8. We also mount a collector to the "return pipe".

9. In the basement, it is not necessary to install it in a special cabinet, therefore, in this case, the collectors are mounted on a metal corner.

10. All collector taps have built-in taps that allow you to turn off a single radiator.

11. The beam distribution in the basement is made on the ceiling. In this case, metal pipes were used.

12. The connection of the heating rays with the collectors is made using a plastic pipe.

13. In the floor slabs, holes are drilled through which the pipes are connected directly to the heater.

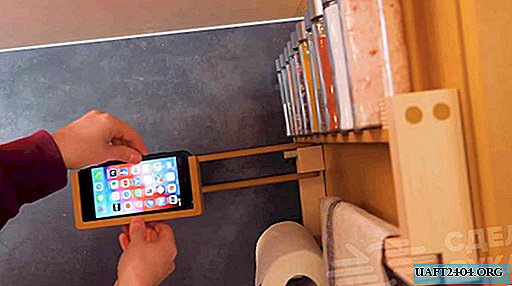

14. A metal-plastic pipe is also used to connect radiators to heating beams.

I have been operating the collector heating system for the second year. There have been no serious failures in the work.

Share

Pin

Tweet

Send

Share

Send